CONSTRUCTION KNOWLEDGE >>

MECHANICAL >>

CONSTRUCTION KNOWLEDGE >>

MECHANICAL >>

PLUMBING

1. What Three Things Must the Plumber Know?

2. It Runs Downhill...But What Then? (a Primer on Sanitary

Sewers)

3. Why are Vents Important?

4. Why Start with the Fixtures?

5. What Should I Know about Pipe?

6. What are the Basics of Sizing a Water System?

7. What Should I Know about Water Treatment?

8. What Should I Know about On-lot Septic Systems?

9. What Should I Know about On-lot Water Systems?

10. What Public Domain Documents are Available for Further Study?

11. Tricks of the Trade & Rules of Thumb for Plumbing

Basics:

What Three Things Must the Plumber Know?

Hot's on left, cold's on right and shinola runs downhill.

It Runs Downhill...But What Then? (a Primer on Sanitary Sewers)

The Plumber should be one of the heroes of modern society. In the 19th century, people moved closer together for work in Industrial Revolution jobs. Typhoid, cholera and dysentery killed thousands due to issues of human waste. Modern plumbing methods, and our Hero the Plumber, helped eliminate this means of spreading infectious diseases. Look at societies today with poor sanitary sewer systems and you'll see a high infant mortality rate and a low longevity.

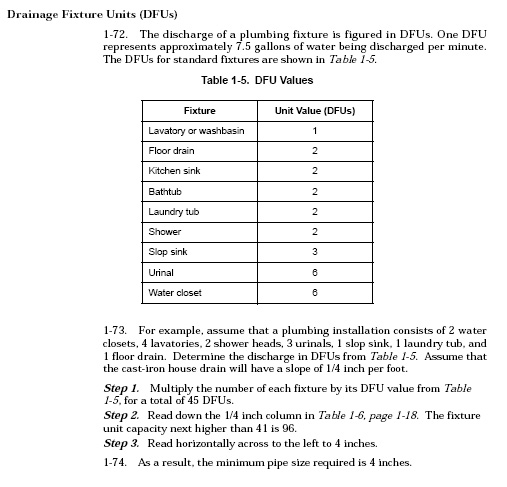

Building Codes recognize this connection between adequately designed and installed sanitary plumbing systems and the public health. To design sanitary systems, most Codes rely on a clever concept called Drainage Fixture Units (DFUs). By setting a DFU quantity for each type of plumbing fixture, the Code considers both how much water a fixture typically passes and the probability of how often the fixtures will be used. In a four story office building with a common toilet rooms on each floor, for example, all the toilets, lavatories, urinals and sinks won't get used at the same moment. If plumbing systems had to be designed for that scenario, pipe sizes would be huge.

The DFU concept allows reasonable sizing of sanitary sewer lines, based on experience from many buildings. Of course, the Plumbing Engineer may decide to design more conservatively than the DFU requirements. A football stadium, where all the beer gets drained from bladders during halftime, needs to be designed for all fixtures to flow at one time. Generally, though, the DFU concept gets used often and the basics should be understood by the Construction Supervisor.

The US Army Field Manual for Plumbing has some helpful guidelines below:

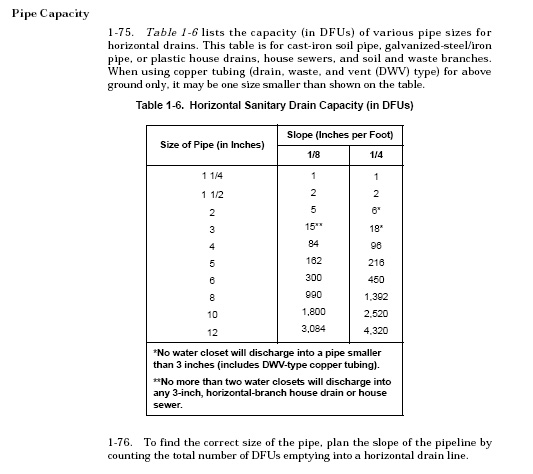

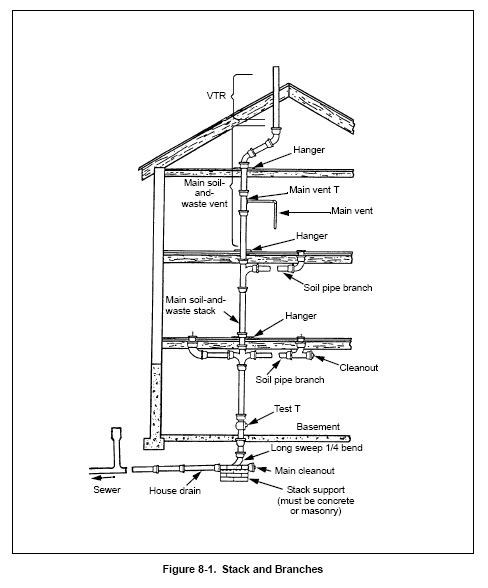

A general understanding of the DFU design process helps the Construction Supervisor understand the importance of the sanitary sewer pipe size and slope. If you'd like a more detailed understanding of the Plumbing Trade, review the public domain documents below. The basics of a plumbing drain system, though, are shown in the graphic below.

Why are Vents Important?

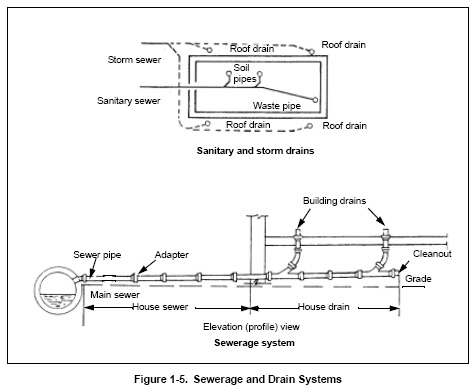

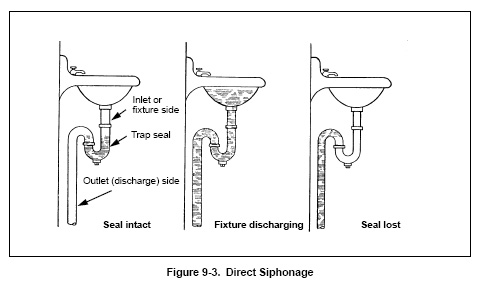

Sewer gas stinks and can make people sick. Maybe not tough guys like you and I, but other people. So plumbing traps prevent the sewer gas from getting up into the inhabited space. The trap keeps that sewer gas down in the pipes where the sewer flows. The details below illustrate:

The concept of the trap seal seems reasonable...keep a water plug between the smelly sewer gas and us. The figure above, though, shows that trap seal being lost as water runs through. That figure shows us why we vent sewer pipes. We need to protect the trap seal. For water to flow, air must replace the volume of water that flows away (think of a straw in a soda with your thumb covering the top of the straw). Since sewer pipes don't run completely full, like that straw full of Coke, the pipe will flow by getting some air over the top of the flowing liquid. But we occasionally lose the trap seal if the flow of water almost fills the pipe. Therefore, vents must be designed and installed so air can get to that trap, protecting the trap water from flowing down the drain and exposing us to sewer gas.

The most common venting is an individual vent, which is commonly required to be at least half the pipe size of the fixture being vented but not less than 1 1/4". Venting complications abound, with common venting, wet venting, waste stack venting, circuit venting, combination drain and vent and island fixture venting. To understand the rules for those vents, you need to consult the Code for your jurisdiction. A simple graphic showing drains and vents is shown below:

A wonderful website, ThePlumber.com, provides some great venting details and professional advice if you want to better understand vents.

Why Start with the Fixtures?

When you start a project and begin to understand the plumbing, I recommend you start by thinking about the fixtures. Many of us have the tendency to get right into the details. We wonder, "What is the depth of that sewer line? Do any other pipes interfere with the run? Can the slope change to make it work?" Instead, we should begin at the beginning.

The sewer lines and the water lines are in the project to serve the plumbing fixtures (which are there to serve the occupants). So begin the project by carefully reviewing the fixtures. Understand what types are selected and how they work. Let's go through a brief review:

Toilets (also called water closets): Toilets carry organic body wastes to the sewer and are made from vitreous china. The main classification for toilets are floor mounted vs. wall hung and tank type vs. flush valve. Toilets have the trap built into the toilet fixture, so the sanitary sewer piping for toilets doesn't include a trap. Here are some toilet options from the US Army Field Manual on Plumbing (which provides much more detailed information and repair instructions) :

If you want to learn lots more about toilets, and anything else to do with actually doing plumbing work, go to ThePlumber.com.

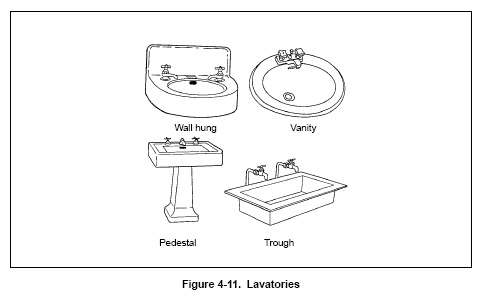

Next to the toilet, you will hopefully find a lavatory, a place to wash your hands after doing the dirty deed. Lavatories may be vitreous china, enameled cast iron, stainless steel or plastic and be wall mounted, pedestal or surface mounted into a vanity cabinet. Here are some lavatory options from the US Army Field Manual on Plumbing (which provides much more detailed information and repair instructions) :

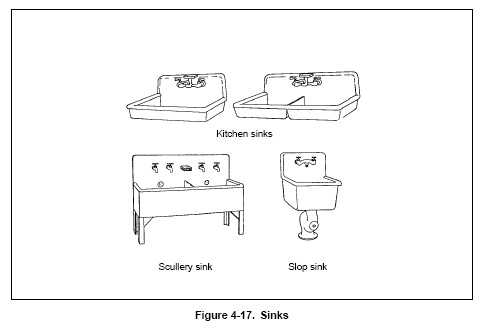

Sinks also allow you to wash your hands, but the sink classification is broader and includes kitchen sinks, mop sinks, slop sinks, bar sinks, etc.

Here are some sink options from the US Army Field Manual on Plumbing.

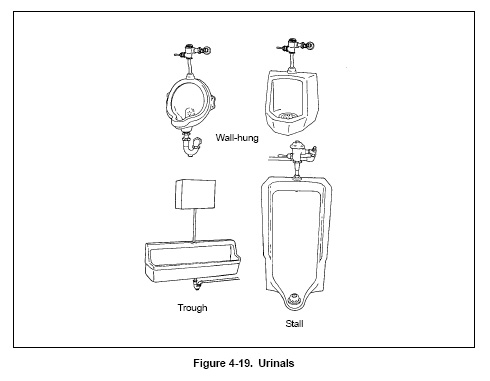

Urinals are also described in the US Army Field Manual on Plumbing and shown below.

Other plumbing fixtures include showers, bathtubs, water fountains,

bidets, whirlpools, and garbage disposals. An internet search on any of

these items will provide more specific information.

![]()

What Should I Know about Pipe?

Most plumbing codes have lots of information on pipe and allow all sorts of pipe options you'll probably never see. Cast iron pipe, for example, gets included in almost every plumbing code, but I haven't seen any cast iron pipe installed for quite a while. All sorts of high tech pipe types also are approved which never get used in normal buildings. So between the old and the new, lots of pipe options makes for confusing codes.

Let's try to cover the pipe basics that you'll likely see on a jobsite. Sanitary sewers inside buildings most often get built from PVC schedule 40 pipe, while sewers outside buildings often use PVC SDR-35 pipe. PVC schedule 40 pipe uses glued connections while PVC SDR-35 has gasketed-joint, slip-in connections. The tables below show some other attributes of various common pipe sizes.

PVC Schedule 40 pipe

| Nominal Pipe Size | Inside Diameter (I.D.) | Outside Diameter (O.D.) | Wall Thickness | Weight per Foot | Maximum Water Pressure |

| inch | inch | inch | inch | pound | psi |

| 1" | 1.03 | 1.32 | .13 | .33 | 450 |

| 1 1/2" | 1.6 | 1.9 | .15 | .54 | 330 |

| 2" | 2.05 | 2.4 | .15 | .72 | 280 |

| 3" | 3.05 | 3.5 | .22 | 1.5 | 260 |

| 4" | 4.0 | 4.5 | .24 | 2.12 | 220 |

| 6" | 6.03 | 6.63 | .28 | 3.73 | 180 |

| 8" | 7.94 | 8.63 | .32 | 5.62 | 160 |

| 10" | 9.98 | 10.75 | .37 | 8.0 | 140 |

| 12" | 11.89 | 12.75 | .41 | 10.54 | 130 |

PVC Schedule 80 pipe

| Nominal Pipe Size | Inside Diameter (I.D.) | Outside Diameter (O.D.) | Wall Thickness | Weight per Foot | Maximum Water Pressure |

| inch | inch | inch | inch | pound | psi |

| 1" | 9.36 | 1.32 | .18 | .42 | 630 |

| 1 1/2" | 1.48 | 1.9 | .2 | .71 | 470 |

| 2" | 1.91 | 2.4 | .22 | .98 | 400 |

| 3" | 2.86 | 3.5 | .3 | 2.01 | 370 |

| 4" | 3.79 | 4.5 | .38 | 2.94 | 320 |

| 6" | 5.71 | 6.63 | .43 | 5.61 | 280 |

| 8" | 7.57 | 8.63 | .5 | 8.53 | 250 |

| 10" | 9.49 | 10.75 | .59 | 12.64 | 230 |

| 12" | 11.29 | 12.75 | .69 | 17.38 | 230 |

PVC Schedule 120 pipe

| Nominal Pipe Size | Inside Diameter (I.D.) | Outside Diameter (O.D.) | Wall Thickness | Weight per Foot | Maximum Water Pressure |

| inch | inch | inch | inch | pound | psi |

| 1" | .89 | 1.32 | .2 | .46 | 720 |

| 1 1/2" | 1.42 | 1.9 | .23 | .79 | 540 |

| 2" | 1.85 | 2.4 | .25 | 1.11 | 470 |

| 3" | 2.76 | 3.5 | .35 | 2.31 | 440 |

| 4" | 3.57 | 4.5 | .44 | 3.71 | 430 |

| 6" | 5.43 | 6.63 | .56 | 7.13 | 370 |

| 8" | 7.19 | 8.63 | .72 | 11.28 | 380 |

Note that PVC schedule 40, 80 and 120 pipe all has the same O.D. for a nominal pipe size, but the I.D. changes. These pipes normally come in 10' and 20' sections. Schedule 40 pipe gets used most often, followed by the heavier schedule 80, then the even heavier duty schedule 120.

The term SDR stands for "Standard Dimension Ratio", it's the ratio of pipe diameter to wall thickness. Therefore, all SDR-35 pipe sizes will have the same maximum water pressure. Also the higher the SDR, the more thin the pipe wall is compared to the diameter. Finally, the standard lengths for SDR pipes are 14' and 20'.

PVC SDR-35 pipe

| Nominal Pipe Size | Inside Diameter (I.D.) | Outside Diameter (O.D.) | Wall Thickness | Weight per Foot | Maximum Water Pressure |

| inch | inch | inch | inch | pound | psi |

| 4" | 3.98 | 4.22 | .12 | 1.03 | 120 |

| 6" | 5.87 | 6.23 | .18 | 2.29 | 120 |

| 8" | 7.92 | 8.4 | .24 | 4.05 | 120 |

| 10" | 9.9 | 10.5 | .30 | 6.35 | 120 |

| 12" | 11.78 | 12.5 | .36 | 9.05 | 120 |

PVC SDR-26 pipe

| Nominal Pipe Size | Inside Diameter (I.D.) | Outside Diameter (O.D.) | Wall Thickness | Weight per Foot | Maximum Water Pressure |

| inch | inch | inch | inch | pound | psi |

| 4" | 3.9 | 4.22 | .16 | 1.57 | 160 |

| 6" | 5.75 | 6.23 | .24 | 3.41 | 160 |

| 8" | 7.76 | 8.4 | .32 | 5.78 | 160 |

| 10" | 9.7 | 10.5 | .40 | 8.97 | 160 |

| 12" | 11.54 | 12.5 | .48 | 12.62 | 160 |

Water piping has more common options. I almost never see galvanized iron pipe installed anymore, though it was common years ago. Both cost and problems with long term corrosion and maintenance have forced the decline. Copper tubing, on the other hand, continues to be popular, even with the large price increases in recent years. Of the three wall thicknesses for copper tubing, I've never used the most thin, Type M copper. The most common Type L copper gets used often for water distribution systems (i.e. piping from the water meter or exterior building wall to the plumbing fixtures). Type K copper has the thickest walls and gets used more for water service (i.e. from the water main to the meter or the exterior building wall). Copper tubing also can be rigid (the straight sections) or soft (rolls). ThePlumber.com provides an excellent discussion on water piping and extols the virtues of copper tubing.

PVC pipe and CPVC (for hot water) pipe also get used often, but have a tendency to leak sooner than copper. PEX piping systems (PEX stands for polyethylene cross linked) have become extremely popular in recent years. The PEX systems are simple and inexpensive to install and rarely leak. The main downside is that the flexible piping, when installed in exposed locations, doesn't look as neat and workmanlike as straight pipe. One important thing to remember with PEX tubing, though, is that it deteriorates rapidly when exposed to UV light. So PEX tubing must be kept out of any sunlight.

What are the Basics of Sizing a Water System?

If you've ever taken a shower and heard a toilet flush, you begin to understand that water system design is tricky. Do you know what happened when you got scalded in the shower? The toilet flush demanded a water flow of cold water only (unless you flush your toilet with hot water) which dropped the pressure in the cold water part of the water distribution system. As the pressure drops, the flow drops. On the hot water side, though, no flush, no pressure drop, no change in flow. So in the shower you get the same amount of hot water and less cold water...and that's not good.

A well designed water system reduces this effect. When the pipes are sized correctly for the likely flows, the pressure drops of another use has a smaller effect. Of course, most plumbing Codes further protect the person in the shower by now requiring a temperature actuated mixing valve at the shower that prevents scalding.

Water system design, then, must account for water flows (in gallons per minute), pressure drop from friction in pipes and from elevation changes (in psi) and water velocity (in feet per minute). These varying factors, along with never knowing which combination of plumbing fixtures will require water at the same time makes the water system design complicated.

Similar to sewer design discussed above, the concept of the water service fixture unit (WSFU) helps simplify the process. The Code lists WSFUs for cold water, hot water and total water for each type of plumbing fixture. Then the design water flow in gpm can be found for any section of piping in the system. A water flow chart then shows the pipe size and friction loss options. This section explains the theory, but doesn't give enough information to actually do the design. Go to your Plumbing Code if you want to understand more.

Another basic concept you should understand about water systems is the pressure loss with height. I recommend you memorize that one psi equals about 2 feet of height gain. So a 50' raise from the ground floor to the 4th floor will drop the water pressure by 25psi. If your public water system provides 45 psi at street level, you will have 20 psi at the 4th floor. Since 20 psi is about the minimum water pressure often recommended, this would work. If the building proposed is an 8 story, what happens? We have a 100' rise, which gives about a 50psi pressure drop. Since we are only starting with 45 psi, we won't be getting any water up to the 8th floor. Thus we'd need a booster pump.

The US Army Field Manual 3-34.471 shows a worked example of water system design and several helpful graphs.

What Should I Know about Water Treatment?

I found a wonderful website that explains water treatment simply and clearly. The H24U site has a water treatment FAQs area that will provide you with a good general understanding.

What Should I Know about On-lot Septic Systems?

This Purdue University website explains on-lot septic systems with lots of graphics.

What Should I Know about On-lot Water Systems?

The WellOwner.org website does a good job of explaining all facets of on-lot water systems.

What Public Domain Documents are Available for Further Study?

The

US Army Field Manual for

Plumbing, Pipe Fittings and Sewerage is an excellent

introduction to plumbing. It provides as much information as many

plumbing books available from bookstores...and it's free. If you

don't have a copy of the Plumbing Code with Commentary for your

jurisdiction, use this US Army Field Manual as a way to be familiar

with the basics. This 276 page

handbook is officially called FM 3-34.471(FM 5-420).

Another resource, more useful in design than in

construction, is the US Dept of Defense

Plumbing Systems Manual. It has 60 pages

of information and is officially named UFC 3-420-01 (October 2004).

For information on compressed air systems, review the

US Dept of Defense Compressed Air Manual, officially named UFC

3-420-02FA (May 2003).

The US Dept of Defense has created a guide to

Indoor Radon Prevention and Mitigation. This 42 page has

the official name UFC 3-490-04A (May 2003).

![]()

Tricks of the Trade & Rules of Thumb for Plumbing Basics:

- Hot's on left, cold's on right and shinola runs downhill.

- One Drainage Fixture Unit is defined as 7.5 gallons of water per minute.

- Vent lines in sanitary sewer are there to protect that trap seal, to keep us from smelling sewer gas.

- To understand the plumbing, understand the plumbing fixtures first.

- PVC schedule 40, 80 and 120 pipe all has the same O.D. for a nominal pipe size, but the I.D. changes.

- Every 2' of height in a building drops the water pressure by about 1 psi.