Ned Pelger's blog on construction, design and other weirdness. Email him at ned@constructionknowledge.net

Please help him win his readership competition against his son Lex at the Construction Phone Apps Blog

The number of visitors to this blog has increased substantially in recent months, while the website traffic has been steady. I’m just completing my first three video training segments (that no longer resemble terrorist videos) that I’ll send out in the first edition of the Super Tips Newsletter. I’m hoping the Super Tips Newsletter and the videos will help many more people utilize this site.

One of the most useful, and fun, aspects of this site could be the Forum. It’s wonderful to connect with others that share an interest in construction, both to get suggestions for solving a problem and just to laugh. As an example, check out this Forum about “Old Timer’s Words of Wisdom” from ConstructionTalk.com. I’d really like to get that kind of interaction going on this site.

So here’s my favor request, please post a comment below to help me revise the Forum section:

I know you don’t like posting comments, but I’d really appreciate if you could give me some feedback here. It feels like now is the time to really push ConstructionKnowledge.net to the next level and making the Forum work is an essential part of that. I really appreciate your help.

I love to make things simple. I feel great when I can work on a complicated task and make it understandable for others who aren’t delving into all the details. Sometimes, though, the complexity has a beauty of its own. The subway map of a Tokyo train station shown below has that kind of beauty to me.

Imagine working on the design and construction of that kind of project. Everything still gets broken down into small individual steps (the place where all the actual work gets done), but the scale of the puzzle is so cool.

Imagine working on the design and construction of that kind of project. Everything still gets broken down into small individual steps (the place where all the actual work gets done), but the scale of the puzzle is so cool.

The mostly straight-foward projects we build give me plenty of challenges, and I’m glad I can finish them before I start getting bored. Sometimes, though, it’s good to contemplate the road not taken.

I hate lying. Whether it’s a big whopper some idiot tells or just someone making a commitment that they know they aren’t going to keep, I’ve tried to arrange my business and my life so I don’t have to deal with many liars. I’ve been reasonably successful.

When one of our daughters was about 16, I caught her in a bold-faced lie. I said to her, “You just lied to me, you stood there and told me a lie!” Trying to explain to me the current state of the world, she responded, “Dad, that’s what people do when they get caught. They lie.” I had to laugh at her honesty about lying and her desire to help me see the light.

Dereck Hench (Construction Supervisor) and I are building a bunch of 24 and 32 unit apartment buildings. We have about a third of the 320 apartments built and occupied. Dereck just told me about a Drywall Finisher who needed to get some water in one of the occupied buildings. Rather than going outside to one of the many exterior wall hydrants, he unscrewed the sprinkler cap and got a bucket of water from the sprinkler system.

As you can imagine, the water flow switch activated the fire alarm and alerted the fire department, who responded to the site with sirens and flashing lights. As Dereck was trying to figure out what happened, he asked the Drywall Finisher if he got water from the sprinkler system (I wouldn’t have even thought to ask). The fellow said, “No, not me.”

Dereck looked into the drywall bucket and saw the dark black water and knew he had a liar on his hands. Dereck usually responds a bit more forcefully to situations than I do (a good combination) and it’s unlikely that fellow will ever touch a sprinkler system valve again.

Over the years I’ve worked with many subs who promised crews the next day then simply didn’t send them. The lies than flowed about what happened between their comittment and their lack of delivery. I got tired of the same guys telling the same lies. Now, if I can’t rely on someone to be straight with me, they just don’t even get a chance to bid. Then I don’t get tempted by a low bid number to again endure the aggravation of working with liars.

You probably don’t have the luxury of choosing who you work with, but you can pay attention to a few things. Do you lie when it’s convenient or try to be straight? Do you panic lie (get nervous and just say what the other person wants to hear)? Do you hold others accountable when they lie to you, willing to confront them and find out what’s really going on?

I challenge you today to commit to be a person of truth. You’ll discover your life has much less stress because you don’t have to keep track of the lies. You’ll also build better relationships with everyone you encounter.

While TBW and I were in Las Vegas for the World of Concrete, we toured Hoover Dam. I’ve wanted to see it for years and was even more impressed than expected. The width of the dam was much less than I’d imagined, but the height astounded me. The design engineers found a perfect spot to build a dam, in a steep canyon with the Colorado River running through (as shown in the photo below):

Built during the Great Depression, many of the workers moved their families to the area for the duration of the project. Work was hard to find in those times and many more men applied than got hired.

Some of their jobs intrigued me. The High Scalers lowered down from the top of the cliffs in rope bosun’s chairs. These guys worked the rock faces of the cliffs, drilling, blasting and cleaning out shot rock. They would just bounce out of the way during the blast. This was the most dangerous and highest paying of the trades.

Our guide expressed amazement that anyone would take that much more risk for only a nominally higher pay. Knowing construction sites, though, this fact didn’t surprise me. The High Scalers were the stars of the project, the cool guys, what’s some extra danger in the face of that?

One of these High Scalers got tired of having guys work above him and accidentally drop rock pieces or tools down on him. He wore a baseball cap, but that didn’t cushion the hit too well. So he took his baseball cap and dipped it in pane tar, let it harden, dipped it again and repeated the process for a few days. Then he had a hard hat that did cushion the blows. Other guys saw how well this worked and made their own hard hats. Then the contracting company saw the value and had thousands of hard hats made. The hard hat has been found on job sites ever since.

Some other job titles amused me. Powder Monkeys were the men who handled dynamite, blasting caps and blasting powder. Grunts were electrician’s helpers.

Our tour guide told us that 96 men died on site during the construction of Hoover Dam. The contracting company had a contract agreement to pay death benefits for workers killed on site. The government generally did not require such a payment. Therefore, after any accident the company tried to get the worker into an ambulance and off site ASAP, because if they died enroute to a hospital, at the hospital, or any place offsite, the company no longer had to pay death benefits. There are no clear records for how many people died offsite.

You may have heard the legend that the bodies of several workers were left in Hoover Dam concrete pours. In fact, the concrete was all poured in 8″ lifts and left to cure, with the next pour being at another location. So no bodies were left in the dam. It would be like having a worker buried in concrete on a slab on grade floor pour.

While walking across the dam, we could see theHoover Dam Bypass project being built.The beauty of those two concrete spans extending out to each other makes me smile.

Since the 2001 terrorist attacks, Hoover Dam has been closed to large trucks and buses carrying luggage, so this bypass bridge will carry most of the traffic when completed.

Hoover Dam was built to provide water for California and the surrounding states (electrical power was almost an afterthought) and jobs for unemployed men during the Depression. Will our Stimulus Plan fund some grand projects that make America substantially more productive?

I came across the story of John Harding, a 50 year old Construction Superintendent from Valencia, CA, this morning. He lost his residential superintendent job 18 months ago and hasn’t been able to find another. He stated, “It’s never taken me longer than two weeks to find another job”. Recently his unemployment benefits ended and he had to sell his work truck.

Knowing that Valentine’s Day was coming soon and wanting to find a nice present for his girlfriend, John wasn’t sure what to do. He found his answer in a Jeweler’s generosity. Apo Yessayan, owner of Classic Designs Jewelry, decided to give away 100 sterling silver diamond heart pendant necklaces to residents who lost a job or a home. The necklaces retail for up to $290 each and come in a gift-wrapped velvet box.

“We understand that the economy is hurting people in the community, and we are a part of the community. We want to help out, plain and simple,” Yessayan said. “It’s a way of saying thank you for supporting our local business and a small way of giving back.”

Harding continues to send out resumes and promote his handyman business. He says, “It takes a person with a generous heart to do something like this for people. I’ve never run into this situation before and to see someone going out of his way and sacrificing his own profit for other people makes me feel more upbeat.”

If you have the chance to help someone in these challenging times, take it.

I don’t think you’re going to like the answer. Most Americans have never seen hard economic times, much of the rest of the world lives it daily. I’m a big fan of the American system, especially our productivity, and strongly believe we will be bouncing back. Unfortunately, we could have a ways down before we start heading back up.

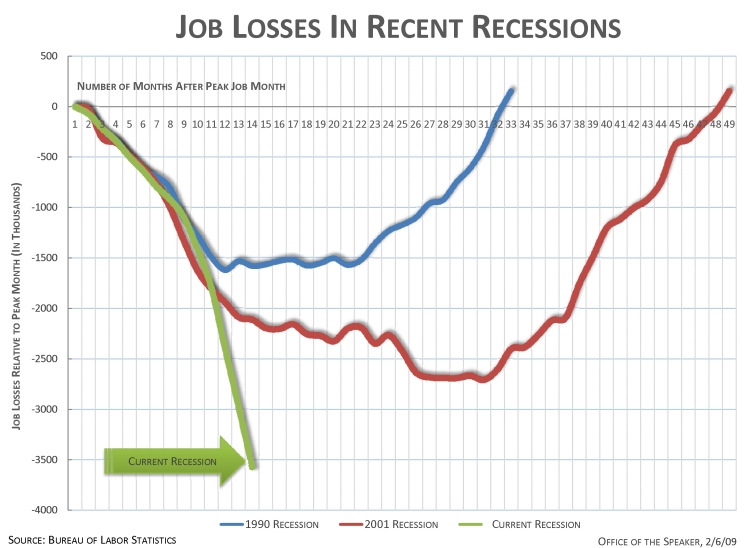

This chart from The Gavel Blog shows the job loss per month for the 1990 recession in blue and the 2001 recession in red. The green line shows the current recession. While the other recent recessions skipped many areas of the economy, this one will touch everyone.

Lots of people complain about our ineffective government, but the economy simply overwhelms what government can usually do to control it. Last fall was an example of the Treasury Department acting well. On the night of September 15, 2008, an electronic run on money market accounts took place. Within 2 hours, $550 billion was withdrawn from money market accounts. The Treasury Department stepped in, shut down the system and stopped a total collapse from occurring. Rep.Kanjorski from PA recently stated:

“The Treasury opened its window to help. They pumped a hundred and five billion dollars into the system and quickly realized that they could not stem the tide. We were having an electronic run on the banks. They decided to close the operation, close down the money accounts, and announce a guarantee of $250,000 per account so there wouldn’t be further panic and there. And that’s what actually happened. If they had not done that their estimation was that by two o’clock that afternoon, five-and-a-half trillion dollars would have been drawn out of the money market system of the United States, would have collapsed the entire economy of the United States, and within 24 hours the world economy would have collapsed.”

That’s some scary stuff. Today, in Russia, people are so scared of the stability of the ruble, that major construction firms are bartering their services. That means major construction firms are advertising that they will accept bartered items, like food or heavy equipment, for payment for their services.

Most of our economic prosperity is based on the confidence that the system is stable and people will do what they say they will do. With those assumptions, we can leverage our limited resources, as a business or as a country, and create extra value. If we lose the confidence, life gets much harder to live.

Sorry to be gloomy, we will get through this. Just don’t make the mistake of thinking we already are.

At the World of Concrete Exposition in Las Vegas this week, I walked miles past exhibits of concrete batch plants, ready-mix trucks, pumpers, assorted tools, rebar bending machines, forming systems, chemical companies and related equipment. The word of the day seemed to be green. Contrary to Kermit the Frog, it turns out it is easy being green…just use concrete. I suppose since concrete gets produced from mostly local materials (aggregate from the nearby quarry), there is a sustainable aspect.

Going a step further down the green path, lots of manufacturers of rigid foam stay in place form systems showed how their walls can be stacked by workers with no experience and provide a highly insulated and inexpensive wall. Having evaluated these systems a few times, I disagree. The stay in place foam forms look great, but can’t compete with traditional framing on either first cost or life cycle cost.

An amazing assortment of products related to concrete get displayed at the Expo. One firm demonstrated a massage system that provided electrical stimulus to relieve wrist and lower back pain. As I walked by the booth, I saw the demonstrator placing the stimulus pads quite low on some guys lower back area. Another fellow walking past commented, “That’s a great place to stimulate him because he’s a real pain in the ass!” I busted up.

All over Las Vegas, we heard lots of languages indicating international visitors. The World of Concrete Expo had many international visitors and many international exhibitors. The inter-connectivity of our current marketplace seems clear. One firm from New Zealand offered a foam pad for hydronic floor heat piping that both held the pipe in place and provided insulation from the ground. They were looking for American distributors. Another floor florming system from Australia knocked-off the Hambro joist concept but used cold formed steel joists for better camber control. Again, they were looking for American distributors to get their product to a mass market, so they could then manufacture it here.

My last World of Concrete visit was about 25 years ago. I was wide-eyed with enthusiasm then, a bit less so now. I’m more skeptical of the wonderful new products. Experience teaches to look at options from more sides, with a more critical eye, because things rarely proceed exactly per the plan. On the other hand, I never want to be an old fogey who lives the mantra, “That’s the way we’ve always done it”.

I’m glad I took the time to explore the World of Concrete. I’ll write later about a couple of amazing seminars I attended.

The Beautiful Wife (TBW) and I spent the day walking the Las Vegas strip. It’s been 30 years since I’ve been here. My weird engineering brain sees the biggest change has been switching the signage from neon to LEDs. The downtown has a Neon Museum that showcases lots of the flashy and flashing neon signs I remember from the 1970s. The photo below is one of my favorite examples:

Today, though, millions of tiny LED lights make screens that show video. In a few years, all those screens will be laser high definition and almost indistinguishable from what our eyes see as reality. Which, as Woody Allen noted, is the only place you can get a good steak.

I heard all the construction had sputtered to a halt on the Strip, but saw otherwise. Lots of crews and cranes were building projects I can barely imagine.

The buildings seem to be getting about 10 times bigger from my last visit as well.

I read an article in Engineering News Record about the MGM Mirage City Center $9.2-billion development. The GC’s self-performing concrete crews moved some rebar from planned locations due to rebar congestion. They didn’t get the structural engineer’s approval, though, and the Building Official rejected the work (long after more work has been built on top). To avoid an expensive re-design, and because the condo units weren’t selling well anyway, the Owners chopped the project from 49 stories to 24 stories. I bet that hurts them in the old Pro Forma.

As TBW and I walked miles, we tried to steep ourselves in the culture of the place. Some of you may assume I’m a cultural cretin, but I enjoy art. In fact, TBW suggested this photo of me admiring some of the wonderful artwork in Las Vegas:

I’ll try to post tomorrow about my experiences at the World of Concrete and eventually get to the Hoover Dam tour. It’s been a great visit so far.

I’m in Las Vegas for the World of Concrete Exposition and a few seminars. The Beautiful Wife (TBW) and I will also take a full day tour of the Hoover Dam. I’ve got a nice little business that runs rather smoothly, thank you very much, so why am I out here expanding my horizons? I value life long learning. If I’m living, I want to continue learning, growing and teaching.

My World of Concrete seminars should teach me a few things about training Construction Supervisors. Getting a useful, take home idea makes the trip worthwhile. I’ll also see all the latest concrete products and technology and learn some things I didn’t even know I needed to know. That’s the beauty of keeping a focus on life long learning.

Perhaps you are just getting started in construction and struggling with the most basic concepts. Perhaps you never understood basic arithmetic and now find that you need to do some of it in your job. You’ve bluffed so far because you really don’t want to look stupid. My advice? Commit to Learning, now and for the rest of your life…but start with now.

I came across these great You Tube videos in which a math teacher simply explains basic concepts while giving examples (which is about the only way I can learn).Check it out, let me know what you think.

[youtube=http://www.youtube.com/watch?v=04eEAxkc4bk]

If you’re reading this blog, I hope you utilize ConstructionKnowledge.net to learn more general technical issues. I’m almost ready to start sending a monthly SuperTips Newsletter which will highlight a few training issues and include videos. As an aside, learning how to produce a decent training video has been a great learning experience for me. My early attempts apparently had the level of quality of terrorist videos.

math videos that are available on my you tube page

Want to Learn Basic Math Better?